Often the first step is the planning and manufacture of molds. Here, we arrange the selected moldmaterials precisely to your requirements and make a suitable choice forms of mold materials as CFK or metal.

For the manufacturing of composite materials we are offering a wide range of different production technologies. Depending on the requirements as number and geometry oft he components we use different production processes among other things:

- Hand layup

- vacuum infusion

- press process

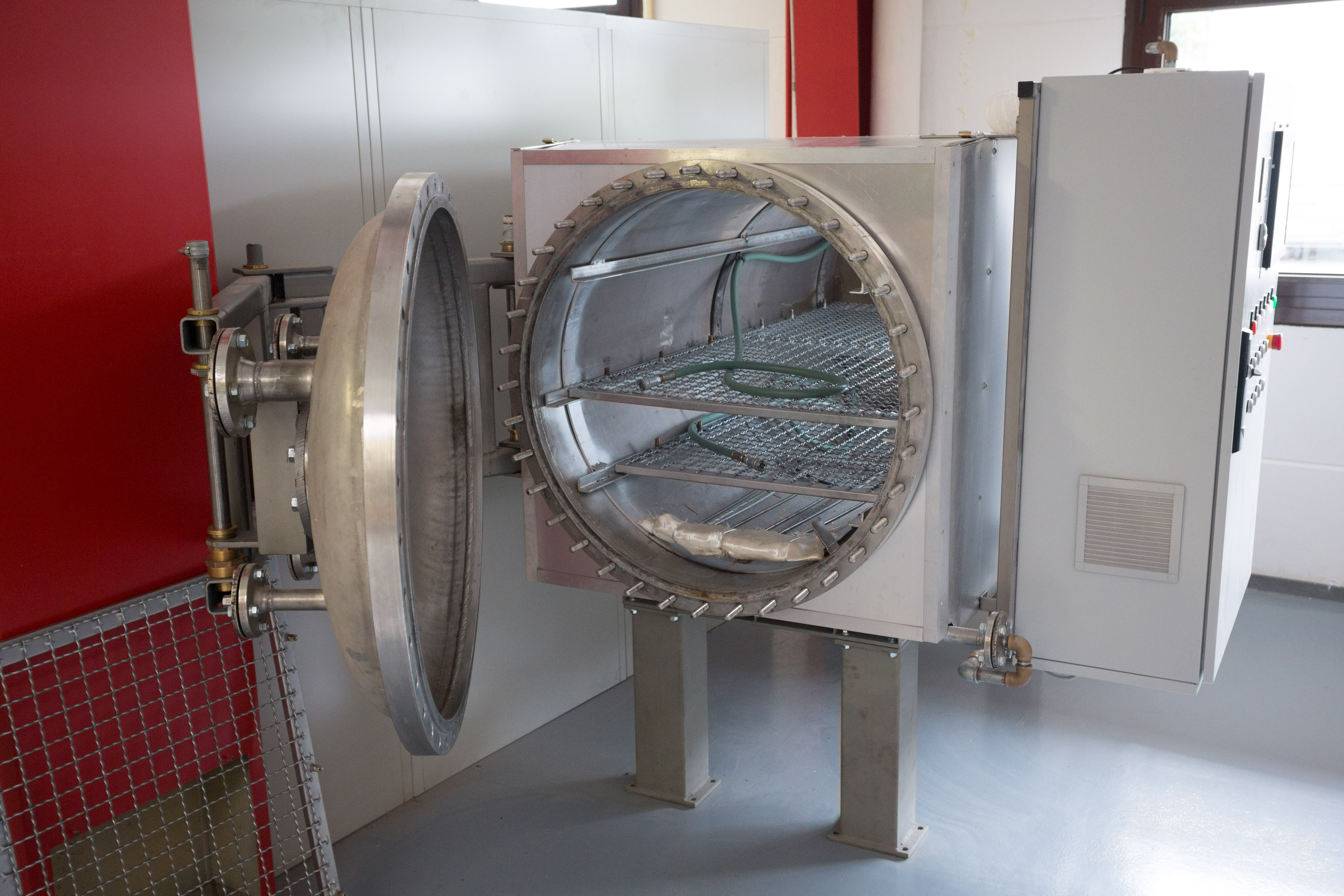

- autoclave process with prepregs

We know the specific benefits and arange the selected method precisely to your requirements.

Especially when we are involved early in projects, youcan benifit from our experience of appropriate composite-based designs.

The integration of electrical and electronic components in the manufacturing process are standard.

An important factor in the production volume of fibre reinforced components is the rework. After removal from the mold the components have to be drawn to the final dimension.

In particular for series components a heavy machining robot with a milling chamber of 90m^2 is available. Here also larger components can be reworked quickly and accurately.

More information will be provided during the next days.